Key Highlights

- Stadler Anlagenbau automates a robot welding system with Panasonic’s Tawers G4 Welding Robot System, reducing cycle times by two-thirds.

- The G4 system delivers improved controller performance, precision welding, and reduced maintenance downtime.

- Panasonic’s DTPS software boosts virtual planning and production scalability for Stadler’s global expansion.

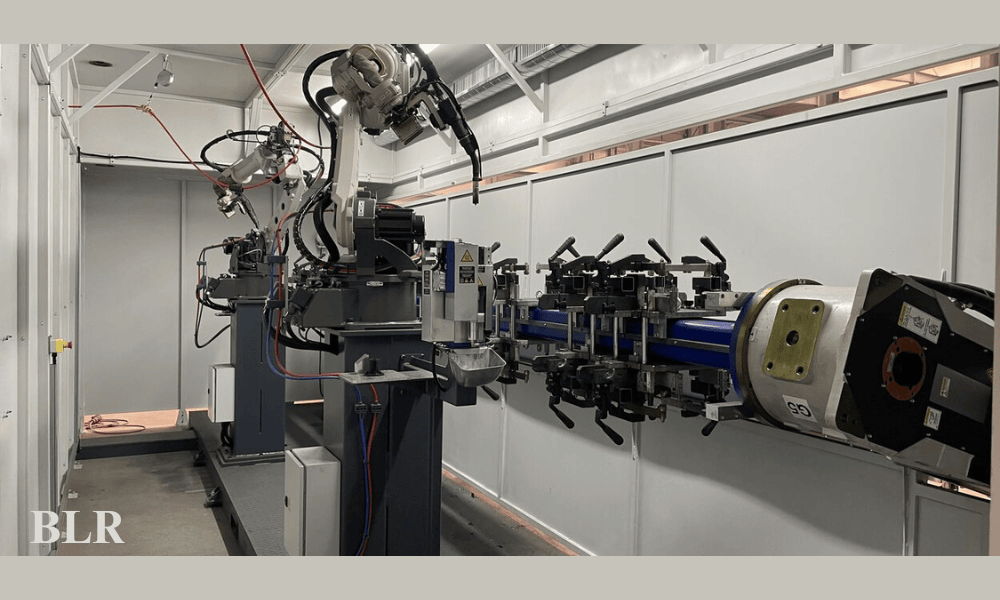

Panasonic Factory Solutions has installed its state-of-the-art Tawers G4 Welding Robot System for Stadler Anlagenbau, a leading manufacturer of recycling and waste sorting systems.

The deployment marks a significant milestone in Stadler’s digital transformation strategy, with automation now cutting welding cycle times by one-third of original time.

Stadler, known for manufacturing all system components in-house, previously utilized Panasonic’s G3 systems for conveyor frame and pre-assembly welding.

The shift to the next-generation G4 system introduces fully integrated process control, optimized robot communication, and enhanced performance reliability.

Automation Reduces Welding Time

The Tawers G4 Welding Robot System features an advanced controller with faster processing power, increased axis speed, and intelligent arc control, all within a single unified platform. Its redesigned high-resolution touchscreen interface enables simplified programming and real-time process monitoring.

The G4 also includes improved contact tips and advanced torch design, ensuring superior weld quality and extended component life.

Together, these upgrades translate into fewer maintenance interruptions and reduced spare part usage.

Bruno Stützle, Head of Production at Stadler Anlagenbau says, “Panasonic’s robot welding systems are easy to operate and maintain. As a result, the cycle and throughput time for some products, including all preparation, has been reduced to one-third of the original time.”

“Aside from scheduled maintenance cycles, the G4 has exhibited faultless reliability since installation. If any questions do arise, support is always quickly available when required, providing peace-of-mind.”

Enhanced Virtual Planning through DTPS Software

Stadler has also adopted Panasonic’s Desktop Programming & Simulation (DTPS) software to optimize virtual production planning.

The platform enables teams to simulate and validate welding programs using imported CAD data before implementation, helping avoid collisions and improve resource allocation.

“Panasonic’s DTPS offline programming software enables us to simulate and optimize production processes in the planning phase. This saves time and reduces the risk of errors and required rework,” Stützle added.

Scaling Global Production Capabilities

The integration of the third Tawers G4 Welding Robot System marks a new era of scalability for Stadler, positioning it to expand into new markets such as electronic waste and textile recycling.Panasonic Factory Solutions will showcase the Tawers G4 Welding Robot System at Schweisstec 2025. This event is taking place from October 21–24 in Stuttgart, at Hall 9, Booth 9505, highlighting its growing leadership in industrial robotics and automated manufacturing solutions.